Great things in business are never done by one person. They’re done by a team of people. We have that dynamic group of peoples

This article dives deep into the world of micro-OLED and microLED microdisplays, exploring their technology, applications, and the significant role they play in shaping the future of AR and VR, especially in devices like the Apple Vision Pro. If you’re interested in understanding the cutting-edge display technologies powering the next generation of immersive experiences, this article is worth reading because it breaks down complex concepts into easy-to-understand language, providing a comprehensive overview of the current state and future potential of these tiny yet powerful displays.

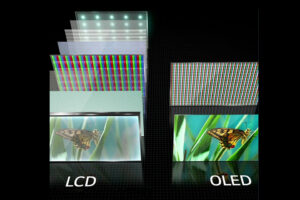

OLED microdisplays are a specialized type of display technology that utilizes organic light-emitting diodes (OLEDs) built on a silicon substrate. Unlike traditional OLED displays found in smartphones and TVs, these microdisplays are incredibly small, often less than an inch in diagonal size. But despite their small size, they pack a high density of pixels, providing high-resolution images even when viewed up close, as in VR headsets. The OLED stands for organic light-emitting diode, OLED microdisplay is built on a silicon substrate, using a standard silicon wafer production process. This allows for the integration of complex circuitry directly onto the backplane, enabling the creation of very compact and highly efficient displays. Each pixel in an OLED display can emit its own light, eliminating the need for a backlight like in LCD displays. This self-emissive nature of OLEDs allows for perfect blacks and an infinite contrast ratio, resulting in stunning image quality.

OLED microdisplays work by sandwiching a layer of organic material between two conductors. When an electrical current is applied, the organic material emits light. The color of the light emitted depends on the type of organic material used. In OLED microdisplays, each pixel is individually controlled, allowing for precise control over brightness and color. This is a significant advantage over traditional LCD displays, which rely on a backlight and color filters to produce an image. The ability of OLEDs to produce their own light also means that they can be incredibly thin and flexible. OLED microdisplays offer the best in class performance when it comes to image quality, color gamut, and response times, making them ideal for applications requiring high performance in a small package. OLED microdisplays are sometimes called OLED-on-silicon, or OLEDoS.

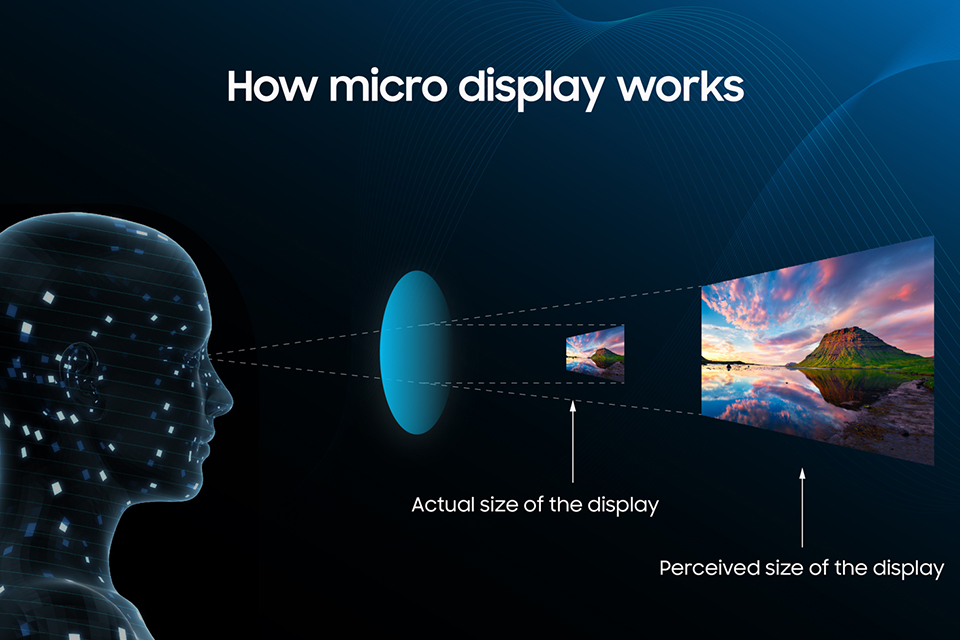

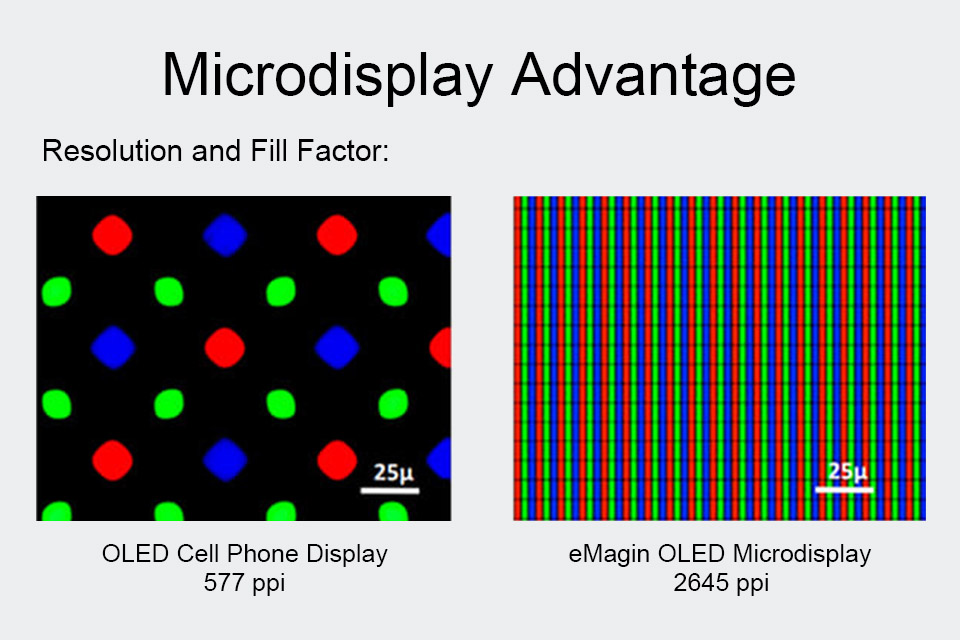

OLED microdisplays are rapidly becoming the preferred choice for high-end VR headsets, and for good reason. Their unique characteristics address many of the limitations of older display technologies in virtual reality applications. One of the most significant advantages is the high pixel density that microdisplays offer. VR headsets require high resolutions to create a believable and immersive experience. OLED microdisplays can achieve pixels per inch (PPI) counts far beyond what is possible with traditional OLED or LCD panels. This high pixel density minimizes the “screen-door effect,” a common issue in older VR headsets where the individual pixels become visible, breaking the illusion of reality.

Another key factor driving the adoption of OLED microdisplays in VR is their exceptional contrast ratio and fast response times. The ability of OLEDs to achieve true blacks and a high contrast ratio enhances the sense of depth and realism in virtual reality environments. Fast response times are crucial for reducing motion blur and ensuring that the display can keep up with the user’s head movements, preventing discomfort and nausea. These features, combined with a wide color gamut, contribute to a more immersive and engaging VR experience. Apple says Vision Pro’s two displays pack 23 million pixels – seven times the pixel density of a 4K TV – into a space about the size of a postage stamp.

| Feature | OLED Microdisplay | Traditional OLED Display |

|---|---|---|

| Size | < 1 inch | Several inches to > 65 inches |

| Pixel Density | Extremely high (thousands of PPI) | High (hundreds of PPI) |

| Substrate | Silicon | Glass or plastic |

| Application | VR/AR headsets, viewfinders | Smartphones, TVs, etc. |

| Brightness | High, suitable for VR/AR | Moderate to high |

| Response Time | Very fast | Fast |

OLED on silicon, also known as micro-OLED, represents a significant advancement in OLED technology. While traditional OLED displays are typically built on glass or plastic substrates, OLED on silicon utilizes a silicon wafer as the substrate. This silicon backplane provides several advantages. First, it allows for the integration of the display’s drive circuitry directly onto the substrate, making the overall display system more compact and efficient. This integration is not possible with the glass or plastic substrates used in traditional OLEDs. The use of silicon also enables the creation of much smaller pixels, resulting in significantly higher pixel densities.

Another key difference is the manufacturing process. Traditional OLED displays are manufactured using a process that involves depositing organic materials onto a glass or plastic substrate in a vacuum chamber. OLED on silicon leverages the well-established semiconductor manufacturing processes used in the production of integrated circuits. This allows for greater precision and control in the production process, leading to higher yields and better performance. While both OLED on silicon and traditional OLED displays share the fundamental principles of OLED technology, such as self-emissive pixels and wide viewing angles, OLED on silicon is specifically designed for small, high-resolution applications like microdisplays, while traditional OLED is better suited for larger-format displays like TVs and smartphones. Micro-OLED is an emissive display technology.

When it comes to microdisplays, the main competing technologies are OLED and LCD (Liquid Crystal Display), including its variant, LCoS (Liquid Crystal on Silicon). While LCD technology, particularly LCoS, has been used in microdisplays and projectors, OLED offers several advantages that make it increasingly attractive. One of the primary benefits of OLED is its self-emissive nature. Each pixel in an OLED display generates its own light, enabling perfect blacks and a very high contrast ratio. In contrast, LCD displays, including LCoS, rely on a backlight that shines through the liquid crystal layer. This can lead to light leakage and a lower contrast ratio.

Another advantage of OLED is its faster response time. OLED pixels can switch on and off much faster than the liquid crystals in an LCD or LCoS microdisplay. This results in reduced motion blur, a critical factor for applications like VR and AR, where fast-moving images are common. Moreover, OLED microdisplays can offer a wider color gamut than LCD microdisplays, leading to more vibrant and accurate colors. It’s important to note that LCD technology, especially LCoS, still has its place in the microdisplay market. LCoS can achieve high brightness levels and has a lower production cost than OLED. However, as OLED microdisplay technology continues to mature and production costs decrease, it is expected that OLED will gain a larger share of the micro display market, particularly in high-end applications such as head-mounted displays and electronic viewfinders.

Sony has established itself as a major player in the OLED microdisplay market, particularly for applications like electronic viewfinders in cameras and headsets for VR. The company has been at the forefront of developing and manufacturing high-quality OLED microdisplays that offer exceptional image quality and performance. Sony’s OLED microdisplays are known for their high resolution, high brightness, and wide color gamut. They are used in a variety of Sony’s own products, including its high-end cameras and VR headsets, as well as in products from other manufacturers.

In addition to manufacturing OLED microdisplays, Sony is also actively involved in research and development to further improve the technology. The company is working on increasing pixel density, improving energy efficiency, and reducing production costs. Sony and others are making a significant impact on the whole OLED industry. Sony’s contributions to the OLED microdisplay market have helped to drive the adoption of this technology in various applications. Their expertise in both display technology and consumer electronics gives them a unique advantage in developing microdisplays that meet the specific needs of different markets. As the demand for high-resolution, high-performance microdisplays continues to grow, Sony is well-positioned to remain a leader in this field.

MicroLED is an emerging micro display technology that is gaining attention as a potential successor to OLED. Like OLED, microLED is an emissive display technology, meaning that each pixel generates its own light. However, instead of using organic materials like in OLEDs, microLED uses inorganic micro–LEDs that are extremely small – sometimes measuring just a few microns in size. MicroLEDs are the tiny LEDs that make up the screen image in each pixel area. These tiny LEDs emit the light that creates the screen image. This fundamental difference in the light-emitting material leads to several key distinctions between the two technologies. One of the main advantages of microLED is its potential for extremely high brightness. MicroLED displays can achieve brightness levels many times higher than OLED displays, making them suitable for use in bright environments, such as outdoors.

Another advantage of microLED is its long lifespan. Inorganic LEDs are known for their durability and longevity, and microLED displays are expected to have a longer lifespan than OLED displays, which can suffer from burn-in over time. MicroLED displays also offer the potential for very high pixel densities, excellent contrast ratio, and wide color gamut. However, unlike OLEDs, microLEDs are not made from organic compounds. MicroLED displays could be a potential type of display for the future smartwatch or AR glasses. MicroLED is an emissive display – which means that every pixel emits its own light (unlike LCD displays that use a separate backlight). Micro-LEDs are highly efficient and bright and microLED displays can be extremely efficient, consuming less power than OLED or LCD displays with equivalent brightness levels.

| Feature | MicroLED | OLED |

|---|---|---|

| Light Source | Inorganic LEDs | Organic compounds |

| Brightness | Extremely high (potentially >10,000 nits) | High (up to ~1,000 nits) |

| Lifespan | Very long | Shorter (susceptible to burn-in) |

| Power Consumption | Potentially very low | Moderate |

| Pixel Size | Very small | Small |

| Manufacturing | Complex and challenging | More mature, but still complex |

| Cost | Currently very high | High, but decreasing |

| Contrast Ratio | Excellent | Excellent (true blacks) |

| Color Gamut | Wide | Wide |

| Response Time | Very fast | Very fast |

The question of whether microLED will replace OLED in microdisplays is a topic of much debate in the display industry. While OLED currently dominates the microdisplay market, particularly in applications like VR headsets and electronic viewfinders, microLED offers several potential advantages that could make it the preferred technology in the future. The OLED vs MicroLED debate is particularly relevant in the context of microdisplays, where the strengths and weaknesses of each technology are amplified. MicroLEDs are smaller than OLEDs, enabling microLED displays to have a higher pixel density.

As mentioned earlier, microLED’s potential for extremely high brightness, long lifespan, and high energy efficiency make it a strong contender. In microdisplays, high brightness is crucial for use in augmented reality (AR) applications, where the display needs to be visible even in bright sunlight. The longer lifespan of microLED is also attractive for devices that are expected to be used for many years. However, microLED technology is still in its early stages of development, and there are significant challenges to overcome before it can be widely adopted. The manufacturing process for microLED microdisplays is complex and costly, and achieving high yields is difficult. OLED, on the other hand, has a more mature manufacturing process, and the costs are gradually decreasing.

The production of microLED microdisplays presents numerous technical challenges that are currently hindering its widespread adoption. One of the biggest hurdles is the transfer process, which involves moving millions of tiny micro-LEDs from their growth substrate to the display backplane. This process must be done with extreme precision to ensure that each micro–LED is correctly placed and aligned. The small size of the micro–LEDs, which can be just a few microns in diameter, makes this process incredibly difficult. Several different transfer methods are being developed, including mass transfer using elastomeric stamps, laser-based transfer, and fluidic self-assembly. Each method has its own advantages and disadvantages, and it is not yet clear which one will become the industry standard to produce microLED microdisplays.

Another challenge is the efficiency of micro-LEDs at very small sizes. As the size of the LEDs decreases, their efficiency tends to drop. This is due to the increased surface area to volume ratio, which leads to more non-radiative recombination of electrons and holes. Researchers are working on improving the efficiency of micro-LEDs through various methods, such as optimizing the LED structure and using new materials. Moreover, the cost of producing microLED microdisplays is currently very high, making them too expensive for most applications. As the technology matures and production volumes increase, the costs are expected to come down, but it is unclear when microLED microdisplays will become cost-competitive with OLED microdisplays.

While VR and AR are currently the most prominent applications for OLED and microLED microdisplays, these technologies have the potential to be used in a wide range of other areas. One such application is in head-up displays (HUDs) for automotive and aviation. HUDs project information onto the windshield or a transparent screen, allowing drivers or pilots to keep their eyes on the road or the sky while still accessing important data. OLED and microLED microdisplays are well-suited for HUDs due to their high brightness, high contrast ratio, and small size.

Another potential application is in medical devices, such as endoscopes and surgical microscopes. OLED and microLED microdisplays can provide high-resolution images in a compact form factor, making them ideal for these types of applications. They can also be used in wearable displays, such as smart glasses and smartwatches, although the challenges of power consumption and brightness need to be addressed for outdoor use in the case of smart glasses, such products are not on the market yet. Furthermore, OLED and microLED microdisplays could find use in projectors, replacing traditional lamps with a more compact and energy-efficient light source. They could also be used in camera viewfinders, providing a brighter and more detailed image than traditional LCD viewfinders. The versatility of OLED and microLED microdisplays opens up a wide range of possibilities for future applications. As the technology continues to develop and mature, we can expect to see these tiny displays enabling new and innovative products across various industries.

Microdisplays, particularly OLED and microLED varieties, are poised to have a profound impact on the future of display technologies. Their unique combination of small size, high resolution, high brightness, and excellent image quality makes them suitable for a wide range of applications that are currently limited by the capabilities of traditional displays. In the near term, microdisplays will continue to drive innovation in AR and VR headsets, enabling more immersive and realistic experiences. As the technology improves and costs decrease, we can expect to see AR and VR become more mainstream, with applications extending beyond gaming and entertainment into areas like education, training, and remote collaboration.

In the longer term, microdisplays could enable entirely new types of devices and interfaces. For example, they could be integrated into contact lenses to create truly seamless augmented reality experiences. They could also be used to create ultra-portable, high-resolution displays for mobile devices, eliminating the need for a large screen size. The development of microdisplays is also likely to influence the evolution of larger displays. The advancements in microLED technology, for instance, could eventually lead to large-format microLED displays that offer superior performance to existing OLED and LCD TVs. Samsung is one of the companies working on microLED displays for the consumer market. More about microLED industry can be found on microLED-info website. Overall, microdisplays represent a significant step forward in display technology. Their ability to deliver high-quality images in a small form factor opens up a world of possibilities for new applications and devices, and they are set to play a key role in shaping the visual experiences of the future.

10 Most Important Things to Remember About OLED and MicroLED Microdisplays:

This article is your comprehensive guide to understanding and navigating the world of LCD display module replacement.

This article dives deep into the lifespan and durability of OLED (Organic Light Emitting Diode) displays compared to LCD (Liquid Crystal Display) screens.

This article dives into the exciting world of augmented reality (ar) lenses, specifically focusing on the development and potential of an interchangeable lens system for ar glasses.

This article dives deep into the world of 0.96 inch OLED display modules, specifically focusing on the 128×64 resolution variant that communicates via the I2C interface.

LCDs, or Liquid Crystal Displays, have become ubiquitous in the digital age, serving as the visual interface for countless devices.

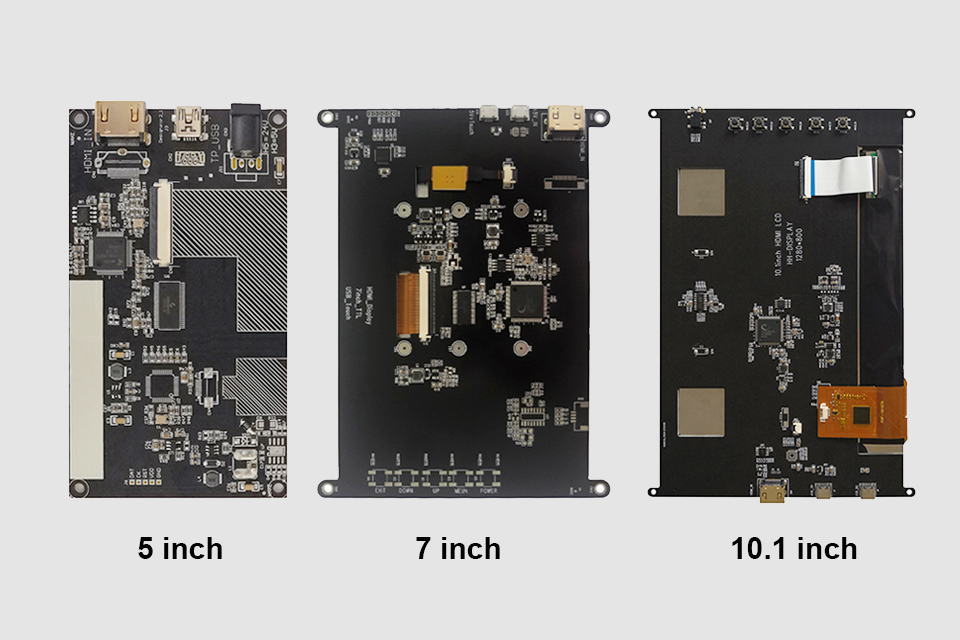

This article explores how to connect an LCD screen to a Raspberry Pi using an HDMI driver board, essentially turning your single-board computer into a miniature HDMI monitor.

This article dives into the exciting world of augmented reality (ar) lenses, specifically focusing on the development and potential of an interchangeable lens system for ar glasses.

This article dives deep into the lifespan and durability of OLED (Organic Light Emitting Diode) displays compared to LCD (Liquid Crystal Display) screens.

@ 2025 display-module. All right reserved.

Fill out the form below, and we will be in touch shortly.