Great things in business are never done by one person. They’re done by a team of people. We have that dynamic group of peoples

This article dives into the world of displays, specifically focusing on LCD technology. We’ll break down the often-confused terms like LCD module, LCD screen, and TFT LCD display, clarifying their individual roles and how they work together. Whether you’re a tech enthusiast, a curious consumer, or someone involved in display module design, this guide will provide a comprehensive understanding of these components, making it worth your time.

LCD stands for Liquid Crystal Display. It’s a type of flat panel display technology commonly used in a wide range of devices, from smartphones and lcd monitors to televisions and digital signage. The core of this technology lies in the use of liquid crystals, a special state of matter that exhibits properties of both liquids and solids. These liquid crystal molecules can change their orientation when an electric field is applied, allowing them to control the passage of light.

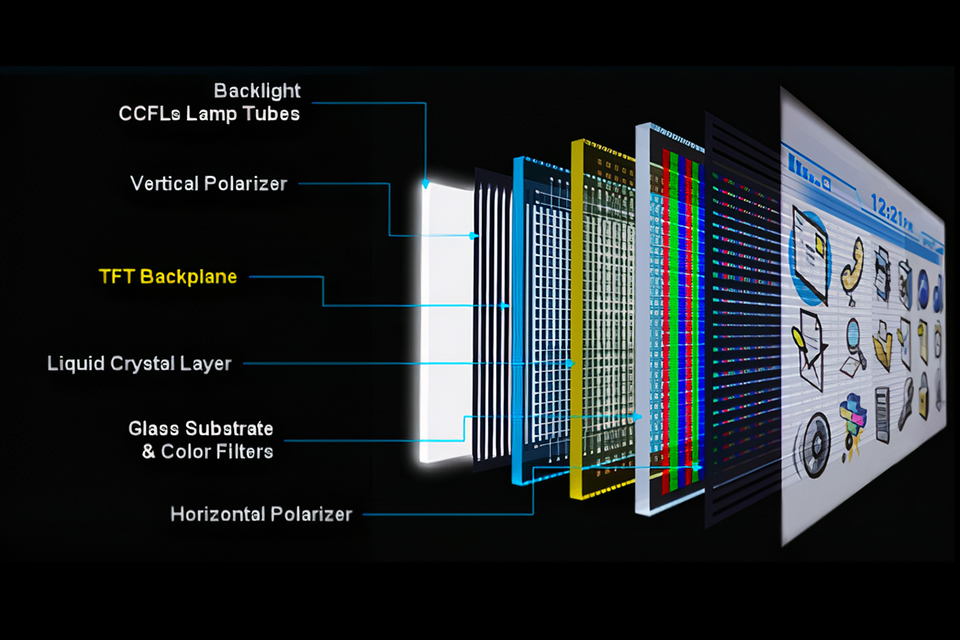

LCD technology revolutionized the display industry by offering significant advantages over older cathode-ray tube (CRT) displays. LCDs are thinner, lighter, consume less power, and produce sharper images. The basic structure of an LCD involves several layers, including two polarized glass substrates with liquid crystal material sandwiched between them, and a backlight source to illuminate the display. An LCD doesn’t emit light itself but manipulates the light from the backlight to create images.

An LCD module, also known as LCM or a liquid crystal display module, is more than just the display itself. It’s a complete assembly that includes the LCD panel, driver integrated circuit (IC), and other components necessary to create a functional display. Essentially, the module is mainly responsible for integrating all the crucial components needed for the LCD to operate seamlessly. Think of it as the brain and nervous system behind the LCD screen.

The LCD module is mainly divided into two primary parts: the LCD screen and the backlight assembly. These two parts are assembled together to form the complete module. While the LCD panel manipulates the light to form images, the backlight provides the illumination needed to make the images visible. The LCD module also houses control circuit boards that receive and process the video signal, converting it into the appropriate electrical signals to drive the individual pixels on the LCD panel.

The principle of liquid crystal display (or principle of lcd display) in an LCD module is fascinating. It hinges on the ability of liquid crystals to manipulate light. The liquid crystal molecules are sandwiched between two glass substrates, each coated with a polarizing filter. When an electric current is applied to specific areas of the liquid crystal panel, the molecules align themselves in a way that either blocks or allows light from the backlight to pass through.

The backlight assembly emits a uniform surface light. This light then passes through the first polarizing filter, which only allows light waves vibrating in a specific direction to pass through. Next, the light encounters the liquid crystal layer. The alignment of the liquid crystal molecules, controlled by the electrical signals from the driver circuit, determines whether the light is rotated or not. Finally, the light passes through the second polarizing filter. If the liquid crystal molecules have rotated the light, it will pass through the second filter and reach your eyes. If the light hasn’t been rotated, it will be blocked. This process occurs for each pixel on the screen, allowing the LCD module to create detailed images. Each pixel can adjust the amount of light that passes through, enabling the display of various shades and colors, ultimately creating the images we see.

The difference between LCD module and LCD panel is crucial to understand. An LCD panel is also refered to as the liquid crystal screen (or lcd screen) itself. This generally refers to a separate screen containing the liquid crystal layer sandwiched between two glass substrates with polarizing filters. The LCD panel is the primary display component of an LCD and is responsible for manipulating the light to form images. However, the LCD panel cannot function independently. It requires additional components to operate, such as a driver circuit and a backlight.

On the other hand, an LCD module is a complete display unit that integrates the LCD panel with all the necessary components to make it functional. This includes the driver IC, control circuit, backlight, and often a frame or housing to hold everything together. Therefore, the LCD module is a ready-to-use display solution, while the LCD panel is just one part of that solution. In simpler terms, a lcd panel has a total of liquid crystal glass, which is only responsible for the function of the screen. In contrast, the lcm is the entire operating system including the control circuit and the lcd itself, which allows the lcd to be connected to the single chip microcomputer to control the display mode and content.

The backlight is a critical component of any LCD, and its role of the lcd screen is particularly important in LCD modules. As mentioned earlier, LCDs do not emit light themselves. Instead, they rely on an external light source to illuminate the display. This is where the backlight comes in. The backlight component typically consists of a series of LEDs (light-emitting diodes) or, in older LCDs, cold cathode fluorescent lamps (CCFLs). The display is that the backlight emits uniform surface light that is then modulated by the liquid crystal layer.

The brightness of the LCD is directly related to the brightness of the backlight tube. A brighter backlight results in a brighter display. However, a brighter backlight also consumes more power. The quality of the backlight also affects the overall image quality of the LCD. An uneven backlight can result in variations in brightness across the display screen, leading to a less pleasing viewing experience. In addition, modern backlights can be designed to dynamically adjust their brightness based on the content being displayed, improving contrast and reducing power consumption.

TFT stands for Thin-Film Transistor. A TFT LCD display is a specific type of LCD that uses thin-film transistors to control each individual pixel on the screen. In a TFT LCD, each pixel has its own dedicated transistor, which acts as a tiny switch that controls the voltage applied to the liquid crystal material. This allows for precise control over the pixel’s state (on or off) and the amount of light that passes through, ultimately shaping the image displayed.

The use of TFT technology significantly improves the performance of LCDs. TFT LCDs offer faster response time (referring to the time taken for the liquid crystal from dark to change state), higher contrast ratios, and wider viewing angle compared to older passive matrix LCD designs. The TFT control allows for each pixel to display the image independently and quickly, resulting in sharper images and smoother motion. This is why TFT LCDs are now the dominant type of LCD used in most applications, including smartphones, laptops, lcd tv, and lcd monitors.

There are various types of LCD modules available, each designed for specific applications and with different characteristics. One way to categorize them is by the type of LCD panel used:

| Type | Description |

|---|---|

| TN (Twisted Nematic) | The most common and affordable type. TN panels offer fast response time but have limited viewing angle and color accuracy. |

| IPS (In-Plane Switching) | Known for their wide viewing angle and accurate color reproduction. IPS panels have slower response time compared to TN. |

| VA (Vertical Alignment) | Offer a good balance between response time, viewing angle, and contrast ratio. VA panels typically have better black levels than IPS. |

Another way to categorize LCD modules is by their interface type, which determines how the module connects to the device it’s driving. Common interface types include:

Response time and viewing angle are two important performance parameters of LCD modules. Response time refers to the speed of the liquid crystal to change from one state to another (e.g., from black to white or from one color to another). It is usually in milliseconds (ms). A faster response time results in less motion blur, which is particularly important for displaying fast-moving content like videos and games. TFT LCDs generally have faster response time compared to passive-matrix LCDs. The response speed of the liquid crystal cell determines how quickly a pixel can change its state, affecting the clarity of motion on the screen.

Viewing angle refers to the angle at which you can view the display screen without experiencing significant degradation in image quality, such as color shifting or loss of contrast. A wider viewing angle means that the display can be viewed from a broader range of positions without noticeable image distortion. TN panels typically have narrower viewing angle compared to IPS and VA panels. TFT LCDs, especially those using IPS or VA technology, offer much wider viewing angle, making them suitable for applications where the display needs to be viewed from different positions.

The manufacturing process of an LCD module is complex and involves multiple steps. It starts with the panel manufacturing of the LCD panel. This involves creating two glass substrates with precise patterns of electrodes and alignment layers. The liquid crystal material is then injected between the two substrates, and the edges are sealed. Polarizing filters are applied to the outer surfaces of the glass substrates. The tft lcd panel is tested for defects before moving onto the next stage.

The next step is to assemble the LCD module. This involves connecting the LCD panel to the driver IC and control circuit boards. The backlight assembly, which typically consists of a light guide plate, diffuser, and LEDs or CCFLs, is also integrated into the module. The entire assembly is then placed within a frame or housing to provide structural support and protection. The final step is to test the complete LCD module to ensure that it meets the required performance specifications. It’s worth noting that the manufacturing process often takes place in specialized facilities, such as those in Shenzhen, a major hub for electronics manufacturing.

LCD modules are ubiquitous in modern society and are used in a vast array of applications. Here are some examples:

LCD modules continue to evolve, with ongoing advancements in areas such as resolution, brightness, contrast ratio, response time, and power efficiency. As technology progresses, we can expect to see even more innovative applications of LCD modules in the future. The principle of lcd display brightness is that the backlight assembly emits uniform surface light, and the light is transmitted to our eyes through the lcd screen. Therefore, the lcd screen is to control the light by pixel to display the image. The role of the lcd liquid crystal panel is to control the display to the input signal, allowing the signal to be transmitted to our eyes through the liquid crystal screen.

The world of displays is constantly evolving, and two technologies consistently dominate the high-end market: AMOLED and OLED.

This article delves into the rapidly evolving world of OLED microdisplays, a cutting-edge display technology that’s transforming how we interact with digital information.

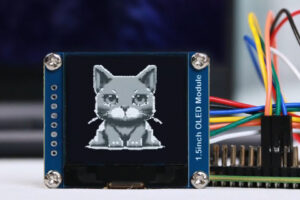

OLED display modules, particularly graphic OLED variants, are revolutionizing the way we interact with devices, offering crisp visuals, vibrant colors (in some cases), and exceptional energy efficiency.

This article delves into the fascinating world of LCD modules, specifically focusing on their integration with Arduino and the capabilities of TFT LCD technology.

LCDs, or liquid crystal displays, are ubiquitous in our modern world, from the screens of our smartphones to our large-screen televisions.

Great things in business are never done by one person. They’re done by a team of people. We have that dynamic group of peoples

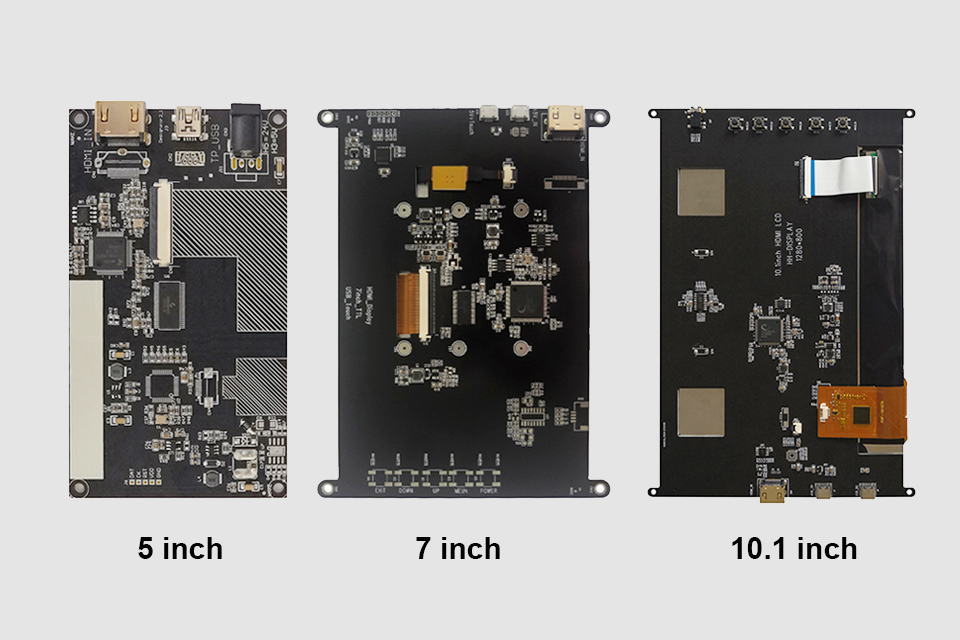

This article explores how to connect an LCD screen to a Raspberry Pi using an HDMI driver board, essentially turning your single-board computer into a miniature HDMI monitor.

This article dives into the exciting world of augmented reality (ar) lenses, specifically focusing on the development and potential of an interchangeable lens system for ar glasses.

This article dives deep into the lifespan and durability of OLED (Organic Light Emitting Diode) displays compared to LCD (Liquid Crystal Display) screens.

@ 2025 display-module. All right reserved.

Fill out the form below, and we will be in touch shortly.