Las grandes cosas en los negocios nunca las hace una sola persona, sino un equipo de personas. Tenemos ese grupo dinámico de personas.

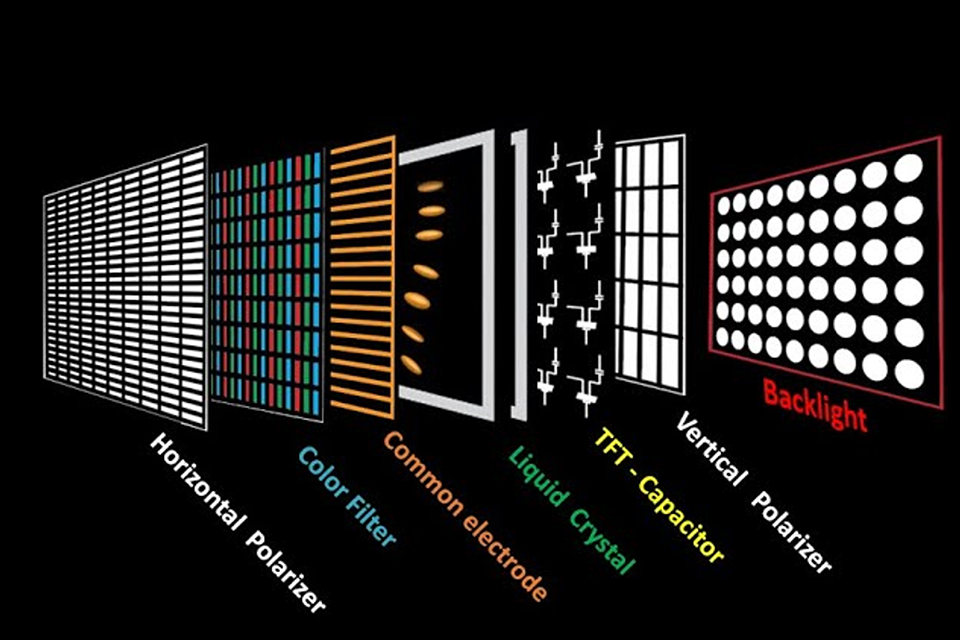

Pantallas LCD, o Pantallas de cristal líquido, se han vuelto omnipresentes en la era digital y sirven como interfaz visual para innumerables dispositivos, desde teléfonos inteligentes hasta Monitores LCD, entendiendo los conceptos básicos Componentes de la pantalla LCD es fundamental para apreciar esta tecnología tan extendida. Este artículo profundizará en el intrincado funcionamiento de Pantalla LCD pantallas, explorando los elementos esenciales que lo componen pantalla de cristal líquido tecnología, como la cristal liquido capa, polarizadores, iluminar desde el fondo, y Pantalla TFT matriz. Vale la pena leer este artículo porque desmitifica Pantalla LCD tecnología, proporcionando una explicación clara y concisa de cómo estas muestra El trabajo y el papel que desempeña cada componente en la creación de las imágenes que vemos todos los días. Al comprender estos Componentes de la pantalla LCDObtendrás una apreciación más profunda de los dispositivos que usar, y estar mejor equipado para tomar decisiones informadas al elegir o solucionar problemas. Pantalla LCD productos. Descubramos también qué Componentes básicos se utilizan en Monitores LCD y Pantalla LCD de 16x2.

Pantalla LCD significa Pantalla de cristal líquidoEs un tipo de pantalla plana. mostrar que usa cristales líquidos en su forma primaria de operación. Pantallas LCD Son populares porque son livianos, compactos y energéticamente eficientes en comparación con tecnologías de visualización más antiguas, como los tubos de rayos catódicos (CRT). Pantallas LCD se utilizan comúnmente en varios dispositivos de visualización, incluidos monitores de computadora, televisores, teléfonos inteligentes, relojes digitales y paneles de instrumentos. La historia de Pantalla LCD se remonta a la década de 1960, cuando el cristal liquido La tecnología fue descubierta y desarrollada aún más por Hitachi.

A diferencia de las pantallas que emitir luz, como OLED (diodo orgánico emisor de luz) muestra, Pantallas LCD operar bloqueando o permitiendo luz pasar a través cristales líquidos. Cristales líquidos Son un estado único de la materia que exhibe propiedades tanto de líquidos como de cristales sólidos. Pueden fluir como un líquido pero tienen sus moléculas orientadas de manera similar a un cristal. Pantalla LCD, el cristal liquido La capa está intercalada entre dos filtros polarizadores y electrodos. Cuando una corriente eléctrica Voltaje Se aplica en todo el cristal liquido células, la orientación de la cristal liquido Los cambios en las moléculas afectan a la polarización de luz pasando a través de ellos. Al controlar el Voltaje aplicado a cada uno píxel, el Pantalla LCD Puede regular la cantidad de luz que pasa a través, creando las imágenes que vemos en la pantallaHay una diferencia significativa cuando se trata de Pantalla LCD vs LED, este último tiene mejor eficiencia energética, pero Pantalla LCD es más barato

Cristal líquido es el corazón de cualquier Pantalla LCDEs un estado único de la materia que tiene propiedades tanto de líquidos convencionales como de cristales sólidos. cristal liquido material utilizado en Pantallas LCD tiene la capacidad de cambiar su orientación molecular en respuesta a un campo eléctrico. Esta propiedad permite Pantalla LCD para controlar el paso de luz y crear imágenes en el pantalla, afectando también Pantalla LCD contrasteEn un caso típico Pantalla LCD, el cristal liquido La capa está intercalada entre dos sustratos de vidrio recubiertos con una capa transparente. conductivo material, como el óxido de indio y estaño (ITO), formando una célula de cristal líquido.

Cuando no Voltaje se aplica, el cristal liquido Las moléculas se alinean en una orientación específica determinada por capas de alineación en las superficies internas de los sustratos de vidrio. En el tipo más común de Pantalla LCD, conocido como nemático retorcido (TENNESSE) Pantalla LCD, el cristal liquido Las moléculas están dispuestas en una estructura de hélice retorcida entre los dos filtros polarizadores, que están orientados a 90 grados entre sí. Cuando luz desde iluminar desde el fondo pasa por el primero polarizador, se convierte polarizado en una dirección específica. En ausencia de un campo eléctrico, la torsión cristal liquido Las moléculas giran polarización del luz por 90 grados, lo que le permite pasar por el segundo polarizador y creando un ambiente brillante píxel. Cuando un Se aplica voltaje A través de la cristal liquido célula, el campo eléctrico provoca la cristal liquido Las moléculas se desenrollan y se alinean con el campo, lo que altera la rotación de luz polarización, causando la luz ser bloqueado por el segundo polarizador y creando una oscuridad píxel. Variando la Voltaje aplicado a cada uno subpíxel, el Pantalla LCD Puede controlar la cantidad de luz que pasa a través, produciendo diferentes tonos de gris o colores cuando un filtro de color se utiliza Los cristales líquidos no emiten luz. ellos mismos, solo lo manipulan.

Desde Los cristales líquidos no emiten luz ellos mismos, Pantallas LCD requiere un externo fuente de luz a iluminar el mostrar. Este fuente de luz se le conoce como el iluminar desde el fondo. El iluminar desde el fondo es un componente crucial de Pantalla LCD tecnología, ya que proporciona la luz que pasa por el cristal liquido capa y, en última instancia, crea las imágenes que vemos en la pantallaEn la mayoría de los modernos Pantallas LCD, el iluminar desde el fondo Consiste en una serie de diodos emisores de luz (LED) dispuestos a lo largo de los bordes de la mostrar panel o detrás de él. Estos también se llaman Retroiluminación LED y proporcionan mejor brillo con menor consumo de energía.

El luz generado por el Retroiluminación LED es típicamente luz blanca. Para garantizar que la luz se distribuye uniformemente a través de pantalla completa, un componente llamado placa guía de luz (LGP) o difusor Se utiliza el LGP, una lámina de material transparente especialmente diseñada que ayuda a esparcir el luz desde LED uniformemente a través de la pantalla. El luz guía También puede incluir otras películas ópticas, como películas prismáticas, que ayudan a dirigir la luz hacia el espectador y mejorar la brillo y uniformidad de la mostrar. La calidad de la iluminar desde el fondo Puede afectar significativamente el resultado general. calidad de imagen del Pantalla LCD, incluyendo su brillo, relación de contraste, y color Precisión. Desigual contraluz Puede conducir a problemas como luz fugas o enturbiamiento, donde algunas áreas del pantalla parecen más brillantes o más oscuras que otras. Por eso iluminar desde el fondo es uno de los Componentes importantes de Pantalla LCD.

En un Pantalla LCDLa imagen que vemos está formada por miles o millones de pequeños puntos llamados píxeles (elementos de la imagen). Cada uno píxel es el elemento controlable más pequeño del mostrar y se puede activar o desactivar, o configurar en diferentes niveles de brillo, para crear la imagen general. Sin embargo, una sola píxel En un Pantalla LCD En realidad, no es una única unidad emisora de luz, sino que está compuesta por unidades más pequeñas llamadas subpíxeles o subpíxeles. Usado típicamente Pantalla LCD tendrá tres subpíxeles Para cada uno píxel – uno para rojo, uno para verde y uno para azul.

Cada subpíxel consiste en una cristal liquido célula cubierta por una filtro de color. El filtro de color es una capa fina de material coloreado que permite que pase únicamente la luz de un color específico (rojo, verde o azul). Al controlar la Voltaje aplicado a cada uno cristal liquido célula, la Pantalla LCD Puede regular la cantidad de luz que pasa por cada uno subpíxel. Cuando los tres subpíxeles están completamente encendidos, los píxel aparece blanco. Cuando todo subpíxeles están fuera, el píxel aparece negro. Al variar la intensidad de cada subpíxel, el Pantalla LCD Puede crear una amplia gama de colores. Por ejemplo, encender el rojo y el verde. subpíxeles manteniendo el azul subpíxel Apagado creará un amarillo píxel. La disposición y control de píxeles y subpíxeles son cruciales para la Pantallas LCD Capacidad de mostrar imágenes detalladas y coloridas. La cantidad de píxeles En un Pantalla LCD determina su resolución: cuanto mayor sea píxel Cuanto más detallada sea la imagen, más detallada será la calidad de la filtros de color y la precisión con la que subpíxeles se puede controlar el efecto color Precisión y generalidad calidad de imagen del mostrarPor eso es Componentes importantes De cada uno Pantalla LCD.

Filtros de color son un componente crucial de Pantalla LCD tecnología, permitiendo la mostrar para producir una amplia gama de colores. Como se mencionó anteriormente, cada píxel En un Pantalla LCD Normalmente se divide en tres subpíxeles:rojo, verde y azul. Cada uno subpíxel está cubierto por una filtro de color que sólo permite luz de ese color específico para pasar. El filtros de color Están hechas de una fina capa de material coloreado, generalmente un pigmento o tinte, que absorbe todas las demás longitudes de onda de luz excepto el color deseado. Por ejemplo, el rojo. filtro de color absorbe verde y azul luz y solo permite rojo luz pasar a través. Del mismo modo, el verde filtro de color absorbe el rojo y el azul luz, y el azul filtro de color absorbe rojo y verde luz.

Cuando luz blanca desde iluminar desde el fondo pasa a través de la cristal liquido capa y la filtro de color, solo el componente de color deseado del luz se transmite a través de cada uno subpíxelLa intensidad de cada componente de color está controlada por el Voltaje aplicado al correspondiente cristal liquido célula, que determina cuánto luz Se permite el paso de luz. Combinando diferentes intensidades de rojo, verde y azul. luz De los tres subpíxeles, el Pantalla LCD Puede crear una gran cantidad de colores. Por ejemplo, para crear un amarillo píxel, el rojo y el verde subpíxeles están encendidos al máximo brillo, mientras que el azul subpíxel está apagado. Para crear un color magenta píxel, el rojo y el azul subpíxeles están encendidos, mientras que el verde subpíxel está apagado. La calidad de la filtros de color utilizado en un Pantalla LCD Puede tener un impacto significativo en la pantallas precisión del color, gama (la gama de colores que se pueden mostrar) y, en general, calidad de imagen. Alta calidad filtros de color Debe tener una excelente transmitancia para el color deseado, un corte nítido para otros colores y una buena uniformidad en toda la superficie. pantalla completaTambién deben ser resistentes a la decoloración o degradación con el tiempo, lo que garantiza que pantallas El rendimiento del color se mantiene constante durante toda su vida útil.

Pantalla TFT significa Película delgada Transistor. Es una tecnología crucial que se utiliza en la mayoría de los aparatos modernos. Pantalla LCD paneles, incluidos Pantalla TFT Pantalla LCD monitores. Pantalla TFT La tecnología implica el uso de una Matriz de transistores de película delgada que se fabrican directamente sobre el sustrato de vidrio de la Pantalla LCD panel. cada subpíxel En un Pantalla TFT Pantalla LCD está controlado por su propio transistor, que actúa como un interruptor para encender el subpíxel encendido o apagado o para regular la cantidad de luz eso pasa a través del líquido cristales. Transistor para cada uno subpíxel permite un mejor control de la brillo y contraste de individuo píxeles. El uso de TFT permite una mayor rapidez Tiempo de respuesta en comparación con los mayores Pantalla LCD tecnologías.

El TFT están dispuestos en un patrón de cuadrícula, con cada transistor conectado a una fila y una columna. Para abordar un problema específico subpíxel, se activa la línea de fila correspondiente y se activa el Voltaje se aplica a la línea de columna. Esto Voltaje carga un condensador en el subpíxel Ubicación, que a su vez controla la orientación de la cristal liquido moléculas y por lo tanto la cantidad de luz que pasa a través de. Una de las principales ventajas de Pantalla TFT Pantalla LCD La tecnología es que permite el direccionamiento de matriz activa, donde cada subpíxel Se pueden controlar de forma independiente y simultánea, lo que permite una mayor rapidez. tiempos de respuesta, mayor contraste proporciones, y ángulos de visión más amplios en comparación con la matriz pasiva más antigua Pantallas LCD. Pantalla TFT Pantallas LCD También suelen tener mejores calidad de imagen, con menos diafonía (interacción no deseada entre cables adyacentes) píxeles) y un control más preciso sobre cada uno subpíxel. Activo matriz encontrado en Pantalla TFT Pantalla LCD es uno de los mas Componentes importantes de Pantalla LCD para lograr una calidad de imagen tan excelente.

Polarizadores son componentes esenciales de Pantalla LCD La tecnología juega un papel crucial en el control de la luz que pasa por el mostrar. Polarizadores son películas delgadas o láminas de material que sólo permitir la luz ondas que oscilan en una dirección específica para pasar, mientras bloquean ondas de luz oscilando en otras direcciones. En un Pantalla LCD, dos filtros polarizadores se utilizan, uno colocado delante del otro cristal liquido capa y la otra detrás de ella.

El polarizadores trabajar en conjunto con el cristal liquido capa para controlar la cantidad de luz que llega al ojo del espectador. Cuando no está polarizada luz desde iluminar desde el fondo Primeros encuentros con la parte trasera polarizador, el polarizador solo permite el componente de la luz que oscila en una dirección específica (el eje de polarización de la polarizador) para pasar a través de esto luz es ahora polarizado. El polarizado luz Luego viaja a través de la cristal liquido capa. En ausencia de un campo eléctrico, la cristal liquido Las moléculas están dispuestas de tal manera que giran. polarización del luz en un cierto ángulo (por ejemplo, 90 grados en un nemático retorcido pantalla). Cuando un Se aplica voltaje A través de la cristal liquido célula, las moléculas se alinean con el campo eléctrico y su capacidad para rotar la polarización de luz se reduce o se elimina. El frente polarizador está orientado de manera que su polarización El eje es perpendicular al de la parte trasera. polarizador. Si el cristal liquido La capa ha girado la polarización del luz por 90 grados (cuando no Voltaje se aplica), el luz puede pasar por el frente polarizador, y el píxel aparece brillante. Si el cristal liquido La capa no gira polarización del luz (cuando un Voltaje se aplica), el luz está bloqueado por el frente polarizador, y el píxel Parece oscuro.

Mediante el control de la Voltaje aplicado a cada uno cristal liquido célula, la Pantalla LCD Puede regular la cantidad de luz que pasa por cada uno píxel y crear diferentes tonos de gris o colores (cuando se combinan con filtros de color) La calidad de la polarizadores utilizado en un Pantalla LCD Puede tener un impacto significativo en la pantallas relación de contraste, ángulos de visión, y en general calidad de imagen. Alta calidad polarizadores Debe tener una excelente transmitancia para luz polarizado en la dirección deseada y bloquea eficazmente luz polarizado en otras direcciones.

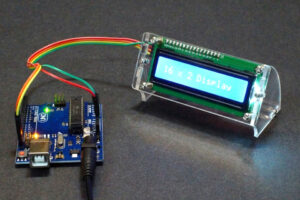

El Pantalla LCD de 16x2 es un tipo popular de Módulo LCD de caracteres Se utiliza comúnmente en varios proyectos electrónicos, incluidos aquellos basados en el Placa ArduinoEl término “16×2” se refiere a la pantallas formato, que consta de 16 columnas y 2 filas de caracteres, lo que permite mostrar hasta 32 caracteres a la vez. Si bien es más simple que el gráfico Pantallas LCD, el Pantalla LCD de 16x2 Todavía depende de varios Componentes importantes para funcionar, incluyendo Pantalla LCD.

Una de las claves Componentes de la pantalla LCD 16×2 es el panel de visualización en sí, que contiene el cristal liquido capa, electrodos y polarizadores, similar a más grande Pantalla LCD pantallas. Sin embargo, en lugar de individuos píxeles, el 16×2 Pantalla LCD Utiliza celdas de caracteres predefinidas para mostrar caracteres alfanuméricos y símbolos. Cada celda de carácter consta de una matriz de puntos, normalmente de 5×8, que se pueden activar o desactivar de forma selectiva para formar el carácter deseado. Pantalla LCD de 16x2 módulo También incluye un tarjeta de circuitos que alberga el Pantalla LCD controlador y otros componentes electrónicos. El Pantalla LCD controlador, como el popular Hitachi HD44780 o un chip compatible, es responsable de recibir datos y comandos del microcontrolador (por ejemplo, un Arduino) y controlar las celdas de caracteres individuales en el mostrar. El controlador Maneja tareas como el posicionamiento del cursor, el cambio de pantalla y la generación de caracteres.

Otro componente importante del Pantalla LCD de 16x2 es el iluminar desde el fondo, que normalmente se implementa mediante LED. iluminar desde el fondo ilumina el mostrar, lo que facilita la lectura en condiciones de poca luz. La mayoría Pantalla LCD de 16x2 módulos permitir el brillo del iluminar desde el fondo para ser controlado, ya sea a través de un potenciómetro o enviando comandos al Pantalla LCD controlador. Además, el Pantalla LCD de 16x2 módulo Generalmente incluye un conjunto de pines de cabecera que permiten conectarlo fácilmente a un microcontrolador u otro tarjeta de circuitosEstos pines incluyen conexiones para alimentación. suministrar (Típicamente usado es 5 V), tierra, líneas de datos (normalmente 8 para comunicación paralela) y líneas de control (por ejemplo, selección de registro, lectura/escritura, habilitación). Cuando se trabaja con un Pantalla LCD de 16x2, es imprescindible consultar el pantallas hoja de datos, que proporciona información detallada sobre la distribución de pines, el conjunto de comandos, las características eléctricas y otras especificaciones.

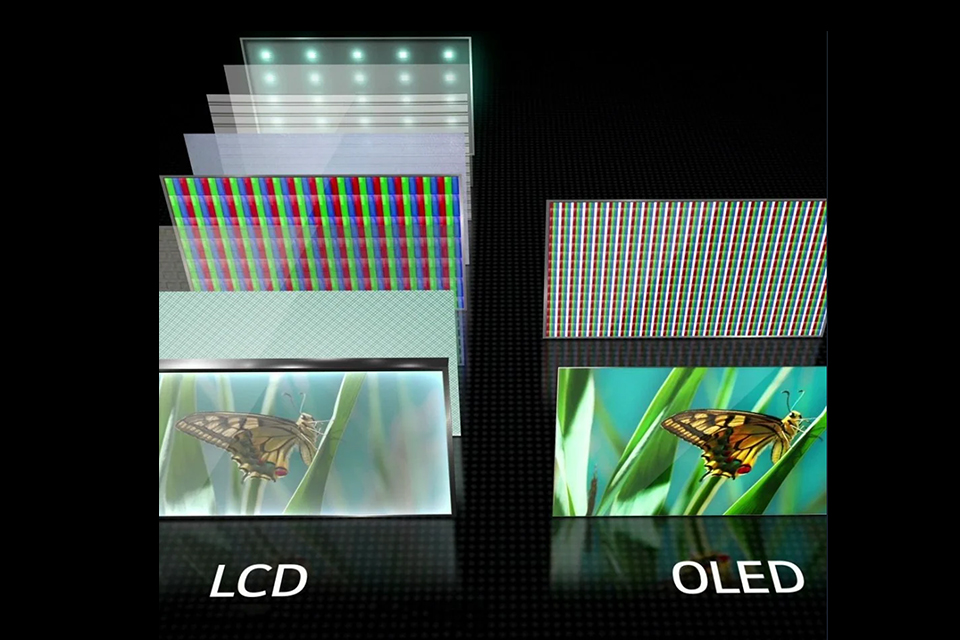

Mientras Pantalla LCD La tecnología ha sido la dominante mostrar Tecnología que ha existido durante muchos años, otra tecnología llamada OLED (diodo orgánico emisor de luz) ha ganado una tracción significativa en los últimos años. OLED muestra ofrecen varias ventajas sobre Pantallas LCD en ciertas aplicaciones, pero también tienen algunos inconvenientes. Comprender las diferencias clave entre Pantalla LCD y las tecnologías OLED pueden ayudarle a tomar decisiones informadas al elegir un mostrar para su proyecto o dispositivo.

Una de las diferencias más significativas entre Pantalla LCD y OLED es la forma en que producen luz. Como hemos aprendido, Pantallas LCD confiar en un iluminar desde el fondo a iluminar el píxeles, y el cristales líquidos actúan como válvulas de luz para controlar la cantidad de luz que pasa a través de. Por el contrario, OLED muestra son autoemisores, lo que significa que cada uno píxel genera su propia luz. Los OLED están hechos de compuestos orgánicos que emitir luz Cuando se aplica una corriente eléctrica, esta diferencia fundamental da lugar a varias distinciones clave en el rendimiento y las características.

| Característica | Pantalla LCD | Pantalla OLED |

|---|---|---|

| Fuente de luz | Externo iluminar desde el fondo (normalmente LED) | Autoemisivo (cada uno píxel genera su propia luz) |

| Nivel negro | Limitado por iluminar desde el fondo Fugas; el negro verdadero es difícil de lograr | Negro verdadero (los píxeles se pueden desactivar por completo) |

| Relación de contraste | Generalmente inferior al OLED | Generalmente más alto que Pantalla LCD (contraste infinito ya que los negros son verdaderamente negros) |

| Tiempo de respuesta | Más lento (puede experimentar desenfoque de movimiento en escenas de movimiento rápido) | Más rápido (prácticamente sin desenfoque de movimiento) |

| Ángulos de visión | Más estrecho ángulos de visión (los colores y el contraste pueden cambiar cuando se mira desde un lado) | Ángulos de visión más amplios (los colores y el contraste permanecen constantes desde casi cualquier ángulo) |

| Consumo de energía | Depende de iluminar desde el fondo brillo; generalmente más alto que OLED para escenas oscuras | Depende del número de lit píxeles; generalmente inferior a Pantalla LCD para escenas oscuras, pero puede ser más alto para escenas predominantemente blancas |

| Espesor | Requiere una iluminar desde el fondo y múltiples capas, haciéndolas más gruesas. | Se puede hacer más delgado y más flexible debido a la ausencia de un iluminar desde el fondo |

| Esperanza de vida | Generalmente más largo, especialmente para el iluminar desde el fondo (Los LED tienen una larga vida útil) | Puede ser más corto, especialmente para OLED azules (los materiales orgánicos se degradan con el tiempo) |

| Tamaño de pantalla | Se puede realizar en tamaños muy grandes, más de 100. pulgada | Usado típicamente En tamaños más pequeños, hasta alrededor de 70-80 pulgada |

| Costo | Generalmente menos costoso, especialmente para tamaños más grandes. | Generalmente más caro, especialmente para tamaños más grandes. |

| Brillo | Depende de iluminar desde el fondo La tecnología, puede ser Más brillante que OLED debido a su potente iluminar desde el fondoPuedes ajustar brillo a un nivel muy alto gracias a la iluminar desde el fondo. | Puede ser menos Más brillante que Pantalla LCD, pero la nueva tecnología puede alcanzar niveles similares. |

El tiempo de respuesta también es más rápido en OLED. En términos de nivel de negro y relación de contrasteLos OLED tienen una clara ventaja, ya que cada uno píxel en un OLED mostrar se pueden apagar por completo, los OLED pueden lograr un negro verdadero, lo que da como resultado una relación de contraste. Pantallas LCD, por otro lado, siempre tenga algo iluminar desde el fondo fuga, lo que significa que las áreas negras de la pantalla Puede aparecer ligeramente iluminado, lo que genera una disminución relación de contraste.OLED muestra También suelen ofrecer visión más amplia ángulos comparados con Pantallas LCD. Con Pantallas LCD, los colores y el contraste pueden cambiar cuando el mostrar se ve desde un lado, debido a la forma en que cristales líquidos y polarizadores Los OLED, al ser autoemisores, mantienen colores y contraste consistentes desde casi cualquier ángulo de visión.

Sin embargo, Pantallas LCD Aún tienen algunas ventajas sobre los OLED. Una es el costo. Pantallas LCD Por lo general, son menos costosos de fabricar, especialmente para los más grandes. pantalla tamaños. Pantallas LCD También tienden a tener una vida útil más larga, en particular para los iluminar desde el fondo, ya que los LED son muy duraderos. Los OLED, al estar basados en materiales orgánicos, pueden degradarse con el tiempo, lo que genera problemas como el efecto de quemado (retención permanente de la imagen) o cambios de color.

Un mantenimiento y cuidado adecuados pueden prolongar significativamente la vida útil de Pantalla LCD pantallas y garantizar un rendimiento óptimo. Si sigue algunas pautas sencillas, podrá mantener su Pantalla LCD en óptimas condiciones y evitar problemas comunes que pueden surgir por negligencia o mal manejo. Una de las importante aspectos de Pantalla LCD El cuidado es la limpieza regular. El polvo, las huellas dactilares y otros residuos pueden acumularse en el pantalla superficie, afectando la visibilidad y potencialmente causando rayones con el tiempo. limpio un Pantalla LCD pantallaLo mejor es usar un paño de microfibra suave y sin pelusa. Limpie suavemente el pantalla con movimientos circulares y aplicando una presión mínima. Evite usar toallas de papel, pañuelos de papel o telas ásperas, ya que pueden rayar la superficie. pantallas superficie delicada

Para manchas o suciedades difíciles, puedes humedecer ligeramente el paño de microfibra con agua destilada o un limpiador especializado. Pantalla LCD Solución de limpieza. Nunca rocíe ningún líquido directamente sobre el pantalla, ya que puede filtrarse por los bordes y dañar los componentes internos. También es una buena idea evitar el uso de productos químicos agresivos, como amoníaco, alcohol o acetona, ya que pueden dañar el revestimiento antirreflejos u otras capas del dispositivo. Pantalla LCD panel. Al manipular Pantalla LCD dispositivos, es importante para evitar aplicar una presión excesiva sobre el pantallaPresionar demasiado fuerte sobre el pantalla Puede dañar el cristales líquidos o las capas subyacentes, lo que lleva a problemas como la muerte. píxeles, decoloración o fugas de luz. Si su Pantalla LCD tiene un Pantalla táctil, ten cuidado con los objetos que usar para interactuar con él. Mientras que los sensores capacitivos modernos tocar pantallas Son bastante duraderos, pero el uso de objetos afilados o abrasivos aún puede causar rayones u otros daños.

Los factores ambientales también pueden afectar la longevidad de Pantallas LCDEvite exponer su Pantalla LCD a temperaturas extremas, alta humedad o luz solar directa durante períodos prolongados. Las altas temperaturas pueden acelerar el envejecimiento del cristal liquido material y otros componentes, mientras que la luz solar directa puede causar pantalla sobrecalentarse y potencialmente provocar decoloración o daños en el polarizadoresLa humedad alta también puede ser perjudicial para Pantallas LCD, ya que la humedad puede filtrarse en el mostrar y provocar corrosión u otros problemas con los componentes electrónicos. Si necesita usar su Pantalla LCD En entornos hostiles, considere utilizar una carcasa o estuche protector diseñado para ese propósito.

Al comprender estos puntos clave sobre Pantalla LCD tecnología, estará mejor preparado para apreciar el funcionamiento de la muestra que enfrenta todos los días, tome decisiones informadas al elegir Pantalla LCD productos y cuide adecuadamente sus Pantalla LCD dispositivos para garantizar su longevidad.

Este artículo profundiza en el fascinante mundo de las micropantallas, centrándose específicamente en la innovadora tecnología OLED 4K desarrollada por Sony Semiconductor Solutions.

Este artículo profundiza en el mundo de las placas controladoras LCD y le ofrece el conocimiento esencial para seleccionar la placa perfecta para su proyecto de pantalla, ya sea que esté reutilizando la pantalla de una computadora portátil o construyendo un monitor personalizado.

Este artículo profundiza en el mundo de las pantallas LCD, centrándose específicamente en el popular módulo LCD de 16×2 caracteres y su integración con Arduino mediante la interfaz I2C.

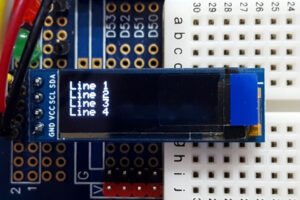

This article dives into the fascinating realm of small OLED displays, exploring their unique characteristics, applications, and the technology that makes them possible.

Este artículo profundiza en el mundo de los módulos de pantalla OLED compactos, centrándose específicamente en la pantalla OLED de 0,91 pulgadas y 128×32 que utiliza la interfaz I2C.

Las grandes cosas en los negocios nunca las hace una sola persona, sino un equipo de personas. Tenemos ese grupo dinámico de personas.

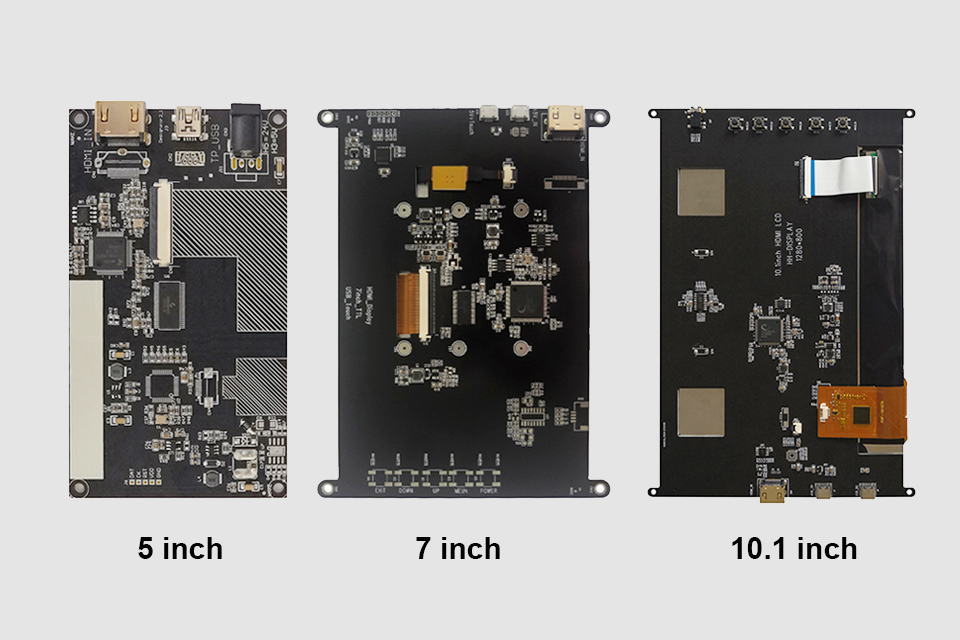

This article explores how to connect an LCD screen to a Raspberry Pi using an HDMI driver board, essentially turning your single-board computer into a miniature HDMI monitor.

This article dives into the exciting world of augmented reality (ar) lenses, specifically focusing on the development and potential of an interchangeable lens system for ar glasses.

This article dives deep into the lifespan and durability of OLED (Organic Light Emitting Diode) displays compared to LCD (Liquid Crystal Display) screens.

@ 2025 display-module. Todos los derechos reservados.

Complete el formulario a continuación y nos comunicaremos con usted en breve.