Great things in business are never done by one person. They’re done by a team of people. We have that dynamic group of peoples

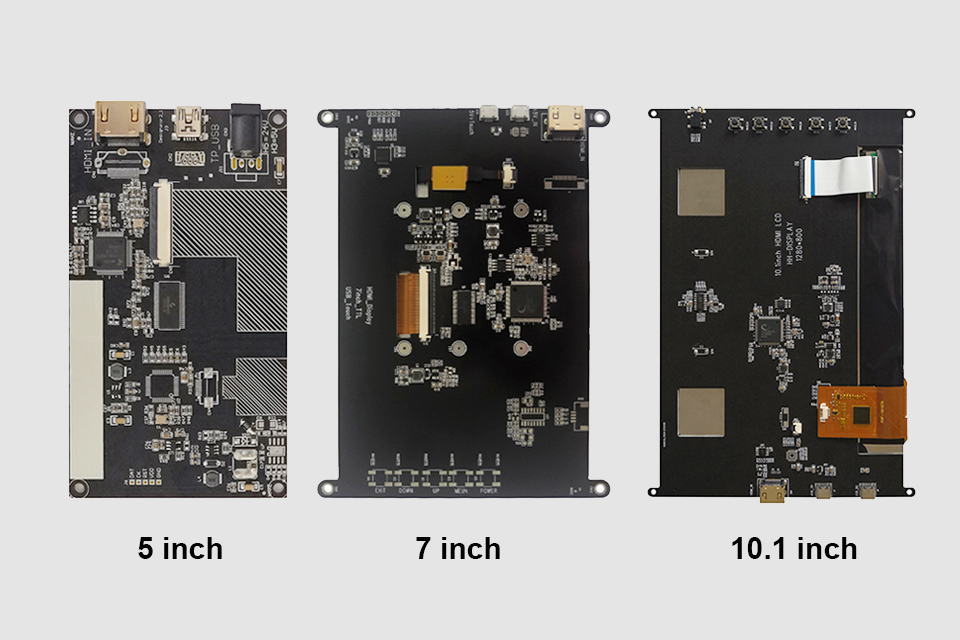

This article is your comprehensive guide to understanding and navigating the world of LCD display module replacement. Whether you’re dealing with a broken screen, upgrading your display, or embarking on a new project that requires an LCD screen, this guide will provide you with the knowledge you need. We’ll explore the different types of LCD display modules, walk you through the process of finding the right replacement for your needs, and answer common questions about compatibility, installation, and more. This article is worth reading because it demystifies the process of LCD display module replacement, empowering you to make informed decisions, save money on repairs, and achieve optimal visual results in your projects. By the end, you’ll understand how to confidently replace the LCD in various applications and find the best 10.1 inch display module replacement screen TFT LCD for your needs or other inch display module replacement screen TFT solutions. Let’s explore what kind of touch screen can we offer.

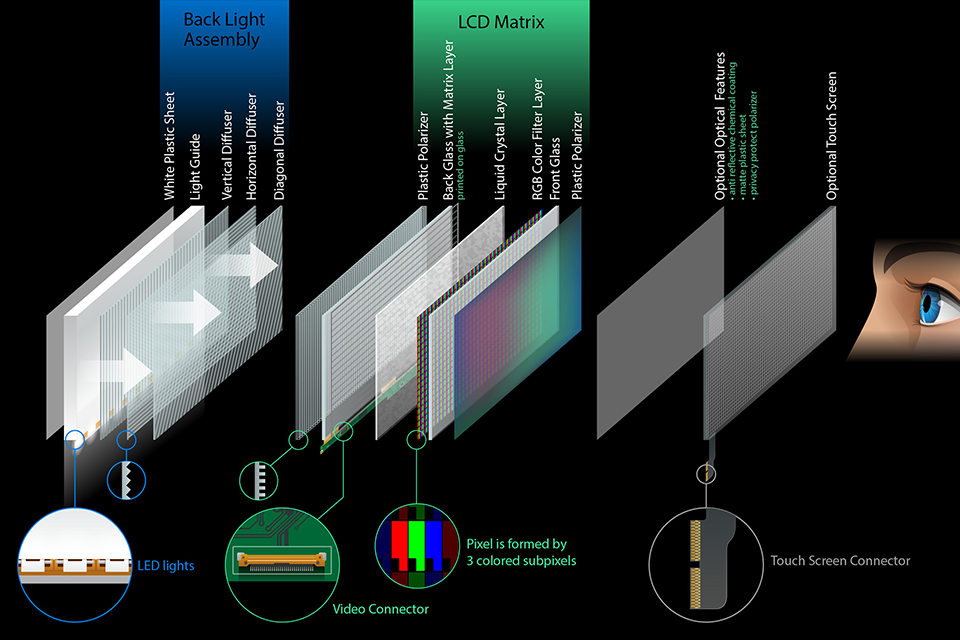

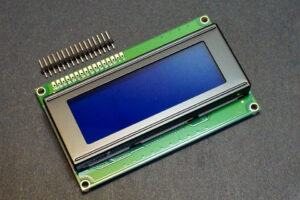

LCDs (Liquid Crystal Displays) have become ubiquitous in modern technology, appearing in everything from smartphones and laptops to industrial equipment and digital signage. When it comes to LCD display modules, several common types cater to different needs and applications. Let’s explore 1 of the most popular options. Character LCD modules are designed to display alphanumeric characters and symbols. They are often used in applications where simple text-based information needs to be displayed, such as in printers, copiers, and industrial control panels. Character LCD modules typically come in standard configurations like 16×2 (16 characters per line, 2 lines) or 20×4.

Graphic LCD modules, on the other hand, are capable of displaying images and graphics in addition to text. They offer greater flexibility in terms of content and are commonly found in applications like handheld gaming devices, medical equipment, and automotive dashboards. Graphic LCD modules come in various resolutions, such as 128×64 or 320×240 pixels. Touch screen LCD modules incorporate a touch-sensitive layer that allows users to interact with the display directly. There are two main types of touch technologies used in LCD modules: resistive and capacitive. Resistive touch screens are pressure-sensitive and can be operated with a stylus or any other object, while capacitive touch screens are more responsive to light touch and offer better clarity. Many other types of LCD modules are available on the market, each with its own set of features and capabilities, like OLED displays that offer better image quality and lower power consumption, but are generally more expensive. It is important to note that many of those types will fit your device so you should choose based on your needs and budget.

Choosing the right LCD display module for your project or replacement needs involves careful consideration of several key factors. One of the most important factors is the display’s resolution, which determines the number of pixels it can display and, consequently, the sharpness and detail of the image. Higher resolutions are generally preferred for applications that require displaying complex graphics or large amounts of text. Display size is another crucial factor. LCD modules come in a wide range of sizes, from small displays used in wearables to large panels used in televisions. The appropriate size depends on the intended application and the available space.

The interface type is also important to consider. Common interface types for LCD modules include parallel, SPI, I2C, and LVDS. The choice of interface depends on factors such as the required data transfer speed, the number of available pins on the microcontroller, and the complexity of the wiring. Other factors to consider include the viewing angle, which determines how well the display can be seen from different angles, the brightness and contrast of the display, which affect its visibility in different lighting conditions, and the operating power and temperature range. It’s also essential to think about whether you need a touch screen and, if so, what type of touch technology (resistive or capacitive) is best suited for your application. Remember to match your display module to your device. By carefully evaluating these factors, you can select an LCD display module that meets your specific requirements and ensures optimal performance in your application. It is also important to match other parts of the device with the display. The type of connector used should be considered as well.

Finding the right replacement LCD display module for your device or project can seem daunting, but by following a systematic approach, you can simplify the process and ensure compatibility. The first step is to identify the specifications of the original LCD display. This information can often be found in the device’s user manual, technical documentation, or on the manufacturer’s website. Important specifications to note include the display size, resolution, interface type, connector type, and model number. This is 1 of the first steps in finding the right part.

If you can’t find the exact specifications of the original display, you may be able to determine them by examining the LCD module itself. Look for any labels or markings on the PCB or the back of the display panel. These markings may contain the model number or other identifying information. Once you have the specifications of the original LCD, you can start searching for a compatible replacement. Online retailers, electronics suppliers, and specialized display distributors are good places to look. When searching, use the specifications you identified earlier as keywords. For example, you might search for “replacement LCD for [device model]” or “10.1 inch 1280×800 display module SPI interface.” It should match your device.

It’s important to carefully compare the specifications of potential replacement LCD modules with those of the original display. Pay close attention to the size, resolution, interface type, connector type, and pin configuration. Even small differences in these specifications can result in incompatibility. If you’re unsure whether a particular LCD module is compatible, consider contacting the seller or manufacturer for clarification. They may be able to provide additional detail or confirm compatibility with your specific device or project. If you need to replace the display always look for the original part number.

It’s not uncommon to encounter situations where you can+not find an exact replacement for a specific LCD screen or display module. This can happen for various reasons, such as the original display being discontinued, the device being too old, or the display being a custom design not readily available on the market. If you find yourself in this situation, don’t despair. There are still several options you can explore.

One option is to search for a compatible LCD screen with similar specifications. While it may not be an exact match, a display with the same size, resolution, and interface type might work as a replacement. However, it’s crucial to pay close attention to the connector type and pin configuration, as even slight differences can cause compatibility issues. You may need to consult the datasheets for both the original and potential replacement displays to ensure they are compatible. This may require some technical experience.

Another option is to consider using a generic LCD module and adapting it to your device or project. This approach often requires more technical expertise, as you may need to design a custom board or modify the existing circuitry to accommodate the new display. You might also need to write custom firmware or modify existing code to interface with the replacement LCD. While this option can be more challenging, it can also provide greater flexibility and allow you to use more readily available display modules.

Replacing an LCD display module may seem like a daunting task, but with the right tools and a systematic approach, it can be a manageable process. Here’s a general step-by-step guide to help you through the replacement process:

Remember to consult the device’s service manual or online tutorials for specific disassembly and assembly instructions if available. If you’re not comfortable performing the replacement yourself, consider seeking professional repair services. It is an easy process, but it requires some technical knowledge.

LCD display modules use various types of connectors to interface with the mainboard or microcontroller. The type of connector used can impact compatibility, ease of replacement, and the overall design of the device. Here are some of the most common connector types for LCD display modules:

| Connector Type | Description | Common Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Ribbon Cable Connectors | Flexible cables with edge connectors, often custom-designed for specific displays. Include FPC and FFC connectors. | Smaller LCD modules, mobile devices, embedded systems | Compact, lightweight,flexible | Can be fragile, may require ZIF connectors for repeated insertions, custom designs can limit compatibility |

| Pin Headers | Rows of metal pins that insert into sockets on a PCB. Common pitches are 2.54mm and 2.0mm. | Character LCDs,some graphic LCDs, developmentboards, hobbyist projects | Simple, low-cost,easy to solder | More bulky than ribbon cables, limited number of pins, may not be suitable for high-speed data |

| ZIF Connectors | Connectors with a locking mechanism (lever or slider) that allows for easy insertion and removal of ribbon cables without damage. | Devices requiring frequent display replacement or upgrades | Protects cables andconnectors from damage during insertion/removal, facilitates easy replacement | Adds cost and complexity compared to non-ZIF connectors |

| LVDS Connectors | Connectors using differential signaling for high-speed data transmission over twisted-pair cables. Often standardized. | Larger, higher-resolution displays in laptops, monitors, industrial equipment | High bandwidth, good signal integrity, standardized connectors improve compatibility | More complex and expensive than simpler connectors, requires specific graphics controllers |

| eDP Connectors | Connectors designed for high-resolution displays, offering reduced pin count, improved power efficiency, and EMI reduction. Increasingly used in modern devices. | Laptops, tablets, all-in-one computers, high-end embedded systems | Supports high resolutions, lower power consumption, reduced EMI, smaller connector size | Newer standard, may not be supported by older devices or controllers |

When selecting an LCD display module or a replacement, it’s crucial to pay close attention to the connector type and ensure that it’s compatible with your device or microcontroller. Using the wrong connector type can lead to connection problems, signal integrity issues, or even damage to the display or other components.

After replacing an LCD display module, you may encounter some common issues. Being prepared to troubleshoot these problems can save you time and frustration. Here are some typical issues and their potential solutions:

Troubleshooting LCD display issues often involves a process of elimination. By systematically checking connections, settings, and drivers, you can often identify and resolve the problem. If you’ve tried these basic troubleshooting steps and are still experiencing issues, it may be time to seek support from the display manufacturer or a professional repair service.

Finding the right replacement LCD display module requires knowing where to shop and what to look for. Several types of retailers and suppliers cater to different needs and levels of expertise. Online marketplaces like Amazon, eBay, and AliExpress offer a vast selection of LCD display modules from various manufacturers and sellers. These platforms are convenient for comparing prices, reading customer reviews, and finding a wide range of options. However, it’s important to exercise caution when buying from third-party sellers and to verify their reputation and the authenticity of the product.

Specialized electronics suppliers such as Adafruit, SparkFun, and Digi-Key are excellent sources for LCD display modules, especially for hobbyists, makers, and those working on DIY projects. These suppliers often curate their inventory, provide detailed product information and datasheets, and offer customer support. They may also offer complementary products like breakout boards, cables, and development kits that can simplify the integration process.

For those seeking industrial-grade or specialized LCD display modules, specialized display distributors like Mouser Electronics, Arrow Electronics, and Future Electronics are good options. These distributors often carry a wide range of displays from leading manufacturers, including those designed for specific applications or industries. They may also offer value-added services like custom display solutions, touch screen integration, and technical support.

Here’s a table summarizing the different types of retailers and suppliers for replacement LCD display modules:

| Retailer/Supplier Type | Examples | Pros | Cons |

|---|---|---|---|

| Online Marketplaces | Amazon, eBay, AliExpress | Wide selection, competitive pricing, customer reviews | Variable seller reputation, potential for counterfeit products, limited technical support |

| Electronics Suppliers | Adafruit, SparkFun, Digi-Key | Curated inventory, detailed product information, good customer support, complementary products | May have higher prices than online marketplaces, may not carry specialized or industrial-grade displays |

| Display Distributors | Mouser Electronics, Arrow Electronics, Future Electronics | Wide range of industrial-grade and specialized displays, value-added services (e.g., custom solutions, touch integration), technical support | May have higher prices, may require minimum order quantities, may not cater to hobbyists or small-volume buyers |

| Manufacturer Direct | Samsung, LG, Sharp, etc. | Guaranteed authentic products, access to latest models and technologies, potential for bulk discounts | May not sell directly to consumers or small-volume buyers, limited selection compared to distributors, may have longer lead times |

When shopping for a replacement LCD display module, it’s important to consider not only the price but also factors like the seller’s reputation, the availability of technical information and support, and the shipping time. Reading customer reviews and comparing specifications across different suppliers can help you make an informed decision and find the best value for your needs. You can also contact the shop and ask for their recommendation.

While replacing an LCD display module can often be a DIY project, there are situations where it’s best to seek professional help. Knowing when to contact a repair shop or technical support can save you time, money, and potential headaches. If you’re not comfortable working with electronics or if you lack the necessary tools or experience, it’s generally a good idea to seek professional assistance. Repair shops that specialize in the type of device you’re working with (e.g., laptops, smartphones, industrial equipment) will have the expertise and equipment to properly diagnose and repair display issues.

Another situation where professional help is advisable is when you’re dealing with a high-value or mission-critical device. If a mistake during the replacement process could result in significant financial loss, data loss, or safety hazards, it’s best to err on the side of caution and let professionals handle the repair. Similarly, if you’ve tried basic troubleshooting steps and are still unable to resolve the issue, it may be time to ask for support.

Many device and display manufacturers offer technical support through various channels, such as phone, email, or online chat. They may be able to provide guidance on troubleshooting, replacement procedures, or warranty claims. Some manufacturers also maintain networks of authorized service centers that are trained and equipped to repair their products. Before contacting a repair shop or support, gather as much information as possible about your device and the display issue. This includes the device model number, the LCD display specifications, a detail description of the problem, and any troubleshooting steps you’ve already taken. The more information you can provide, the faster and more effectively the repair technician or support agent can assist you.

Once you’ve successfully replaced your LCD display module, it’s important to take proper care of it to ensure its longevity and optimal performance. Proper care and maintenance can help prevent damage, reduce the need for future repairs, and keep your display looking its best. One of the most important aspects of LCD display care is regular cleaning. Dust, fingerprints, and other debris can accumulate on the screen surface, affecting visibility and potentially causing scratches. To clean your LCD screen, use a soft, lint-free microfiber cloth. Avoid using paper towels, tissues, or rough fabrics, as these can scratch the display. You can use distilled water, but avoid spraying it directly on the screen.

In addition to regular cleaning, it’s important to handle your LCD display with care. Avoid applying excessive pressure to the screen surface, as this can damage the pixels or the underlying layers. When transporting a device with an LCD display, such as a laptop or a portable monitor, use a padded case or sleeve to protect the screen from impacts and scratches. If you have an LCD display with a touch screen, be mindful of the objects you use to interact with it. While most modern capacitive touch screens are quite durable, using sharp or abrasive objects can still cause scratches or other damage. Stick to using your finger or a stylus specifically designed for capacitive touch screens.

Environmental factors can also affect the performance and lifespan of an LCD display. Avoid exposing the display to extreme temperatures, high humidity, or direct sunlight for extended periods. These conditions can cause damage to the LCD panel, the backlight, or other components. If you need to use your device in harsh environments, consider using a protective case or enclosure designed for that purpose.

By keeping these key takeaways in mind and following the guidance provided in this article, you’ll be well-equipped to tackle your next LCD display module replacement project with confidence. Enjoy your new LCD display!

This article dives deep into the world of interfacing a 16×2 LCD module with microcontrollers like Arduino and ESP32, specifically focusing on the setup without using an I2C module.

This article dives deep into the fascinating world of microdisplays, focusing specifically on the groundbreaking 4K OLED technology developed by Sony Semiconductor Solutions.

AMOLED display modules are rapidly becoming the gold standard in visual technology, offering unparalleled image quality, vibrant colors, and exceptional energy efficiency.

Confused about the alphabet soup of display technologies? This article breaks down the differences between TFT, AMOLED, and IPS displays.

This article dives deep into the lifespan and durability of OLED (Organic Light Emitting Diode) displays compared to LCD (Liquid Crystal Display) screens.

Great things in business are never done by one person. They’re done by a team of people. We have that dynamic group of peoples

This article explores how to connect an LCD screen to a Raspberry Pi using an HDMI driver board, essentially turning your single-board computer into a miniature HDMI monitor.

This article dives into the exciting world of augmented reality (ar) lenses, specifically focusing on the development and potential of an interchangeable lens system for ar glasses.

This article dives deep into the lifespan and durability of OLED (Organic Light Emitting Diode) displays compared to LCD (Liquid Crystal Display) screens.

@ 2025 display-module. All right reserved.

Fill out the form below, and we will be in touch shortly.