Great things in business are never done by one person. They’re done by a team of people. We have that dynamic group of peoples

This article explores the fascinating world of LCD (Liquid Crystal Display) technology, focusing on the essential role of driver boards and controllers in making these displays function. We’ll examine the different types of driver boards, their functionalities, and how they interface with various devices via HDMI and other connectors. Whether you’re an electronics enthusiast, a student, or simply curious about how your screen works, this guide offers valuable insights into the often-overlooked components that power the images we see every day. Understanding the role of the display driver board and its associated components is crucial for anyone looking to build their own display projects or troubleshoot existing ones.

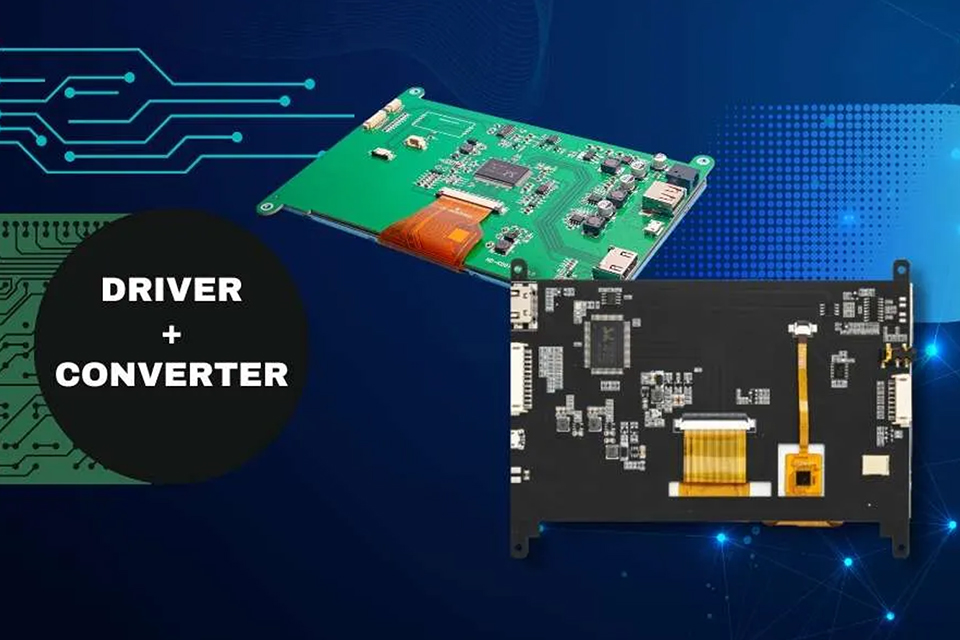

The display driver board, often referred to simply as the driver board, is the unsung hero behind every functional LCD display. It is a crucial piece of electronics that sits between the device you’re using (like your computer or media player) and the LCD panel itself. Essentially, the driver board translates the signal from your device, which could be in formats like HDMI or VGA, into the specific instructions that the LCD needs to display an image. Without this intermediary, the display would remain a blank, unlit piece of glass. The driver board is responsible for generating the necessary voltage and control signals to drive each individual pixel on the display panel. It is the essential component to provide proper video and input and output signal. This is the heart of the operation and allows the display to show various information.

The necessity of the driver board stems from the fact that LCD technology requires a very specific type of control. A computer or media player cannot directly communicate with the display. The display driver board acts as a translator, receiving the input signal and converting it into the necessary electronic signals to drive the display panel. A driver board ensures proper transmission of the image data from the source device to the LCD, maintaining resolution and image quality. It’s the critical link that facilitates a visual representation of the digital signal.

The lcd driver, or often just the driver board, is the electronic circuit that interfaces with the LCD panel and controls the pixels to produce an image. The lcd driver is responsible for receiving and processing the input signal, which can come from a variety of sources through interfaces like HDMI, VGA, or even USB, then converting this signal into specific instructions to activate individual pixels on the lcd screen. This requires precise management of electrical voltage and current. The lcd driver also handles tasks like adjusting brightness and contrast. Key components of an lcd driver often include a controller, power management circuitry, and signal processing units. The lcd driver ensures that the display operates within its designated operational parameters. The driver board converts video signals to signals the panel can use, which includes analog video from VGA or digital video from HDMI.

A typical lcd driver manages the activation of the LCD panel‘s liquid crystal elements. This is often done using a grid of transistors and electrodes. The lcd driver precisely controls the electrical charge applied to each pixel on the display, which determines the amount of light that passes through and, consequently, the color and intensity of each pixel. Different lcd types may have slightly different driver requirements, leading to a variety of lcd driver designs. It also involves the management of the backlight and other essential parameters for optimal performance. An lcd driver ensures smooth transitions of visuals on the screen. LCD devices require precise driver circuits to function as intended.

The controller is another vital component that works in tandem with the display driver board. Often, the controller is integrated onto the driver board itself, but it can also be a separate integrated circuit (IC). The controller is essentially the brains of the operation, interpreting the signal and deciding how to drive the LCD‘s matrix of pixels. The controller receives input from various sources and coordinates their display on the lcd screen. The primary role of the controller is to manage the low-level interactions needed to generate the picture such as pixel driving sequences.

The controller, typically a processor, handles many tasks including processing the input signal, converting it into a format that is suitable for the lcd screen, and managing the timing and synchronization of the display. It controls the scan process and the refreshing of the image on the display, and it ensures that all pixels are activated at the right time. The controller can also be responsible for features such as on-screen menu (OSD) display and managing firmware updates. Additionally, the controller ensures the proper sequencing of data for each pixel, maintaining consistent and high-quality image rendering. The controller is crucial for converting the digital signal to the analogue voltage necessary to manipulate the liquid crystals in the LCD.

The driver board is the central power hub for an lcd display. Its primary role is to take the incoming signal from your source (like a computer or video device) and convert it into a format usable by the lcd panel. Specifically, the driver board ensures the correct voltage is supplied to each pixel in the display. This is a complex process, as it involves managing the current and electrical signals to activate, refresh, and modulate the light that comes from the backlight. The driver board interfaces between the input connections and the display panel, ensuring a seamless and consistent image output. The board work involves multiple electronic circuits all working in perfect synchrony. The driver board receives the video signal and transforms it into the display data needed by the display panel.

A functional driver board also deals with managing the image refresh rate, which is a key factor for fluid motion in video and graphics. For instance, when using a high-refresh-rate gaming lcd screen, the driver board is responsible for quickly and precisely modulating the electrical signal to each pixel to keep the image smooth and tear-free. This includes managing the timing of the horizontal and vertical sync signals and controlling the amount of light that each sub-pixel emits. It’s not just about providing power; it’s about precisely controlling how that power is delivered and timed to each pixel to create a coherent, clear image on the display. The driver board ensures that each pixel is powered efficiently to reduce power consumption while maintaining optimal brightness and contrast. The display driver board is responsible for driving individual rows and columns of pixels, a complex task that it handles efficiently.

An lcd controller board is often used interchangeably with a driver board but in some contexts, it may refer to a more specific set of functions. The lcd controller board is primarily responsible for the interpretation and processing of input signals, such as HDMI, VGA or other digital formats. It manages various video input formats, timing, and sync signals, ensuring the correct display resolution and image quality. The lcd controller board contains a processor that handles the video signal, processes it, and prepares it for display on the lcd screen. In many designs, the lcd controller is embedded on the display driver board itself. The controller board is very often based on a micro processor.

The key difference between an lcd controller board and a driver board, if any, usually lies in their focus. The driver board is more concerned with the physical act of sending the necessary voltage and current to the lcd panel. The lcd controller board, however, deals with the processing of the video signal, its interpretation, and ensuring proper synchronisation. In essence, the controller manages the “what to display” aspect while the driver board handles the “how to display” aspect. The lcd controller board often includes functionalities such as OSD and manages multiple input connections. The lcd controller driver ensures that the received signal is converted properly for the display. In many cases, the functions of the controller board and the driver board are combined into one unit, particularly in simpler display solutions.

The HDMI (High-Definition Multimedia Interface) has become the standard interface for modern lcd display setups. Its importance stems from its ability to carry high-definition digital video and audio signals over a single cable. HDMI simplifies connections, reduces clutter, and ensures high-quality transmission of the video signal from source devices to the display. This is particularly crucial for high-resolution lcds, where preserving the integrity of the signal is paramount for clear and sharp images. An HDMI interface is commonly found in various lcd devices ranging from televisions to computer monitors.

HDMI also supports various video formats, frame rates, and resolutions, making it highly versatile. The use of HDMI means the display receives a digital signal that does not degrade like analog counterparts such as VGA. The importance of HDMI is especially visible in applications where the highest fidelity of video signal and audio quality is needed, such as gaming or watching high-definition movies. The availability of HDMI on a driver board means a wider compatibility with different video sources. The HDMI interface on the driver board simplifies connections and allows the display to be compatible with modern sources. An hdmi cable transmits high-fidelity digital video and audio information, essential for high-quality displays.

TFT lcds (Thin-Film Transistor Liquid Crystal Displays) are the most common type of lcds used in modern display devices. The key difference between TFT lcds and other lcd types lies in the way individual pixels are controlled. In a TFT lcd, each pixel is controlled by its own transistor. This means much greater precision in the way the display is controlled, resulting in better image quality and faster response times compared to earlier LCD designs. This allows for a greater range of color and brightness levels. The transistor in tft lcd technology can control each pixel more effectively than other lcd methods. The use of a transistor for every pixel contributes to the high resolution and better quality of tft lcd technology.

The advantage of tft lcd technology is its ability to produce clearer and sharper images, wider viewing angles, and higher contrast ratios. This makes tft lcds suitable for various applications including computer monitors, televisions, smartphones, and other devices. This technology has become widespread because of its versatility and its ability to deliver high-quality visual experiences. The tft lcd module is an integration of the display and the necessary electronics. TFT LCD panels provide a brighter, clearer, and more vibrant display compared to some older LCD variants. TFT technology is dominant in the LCD display market because of its superior performance and flexibility. The tft technology is the base of modern LCD production.

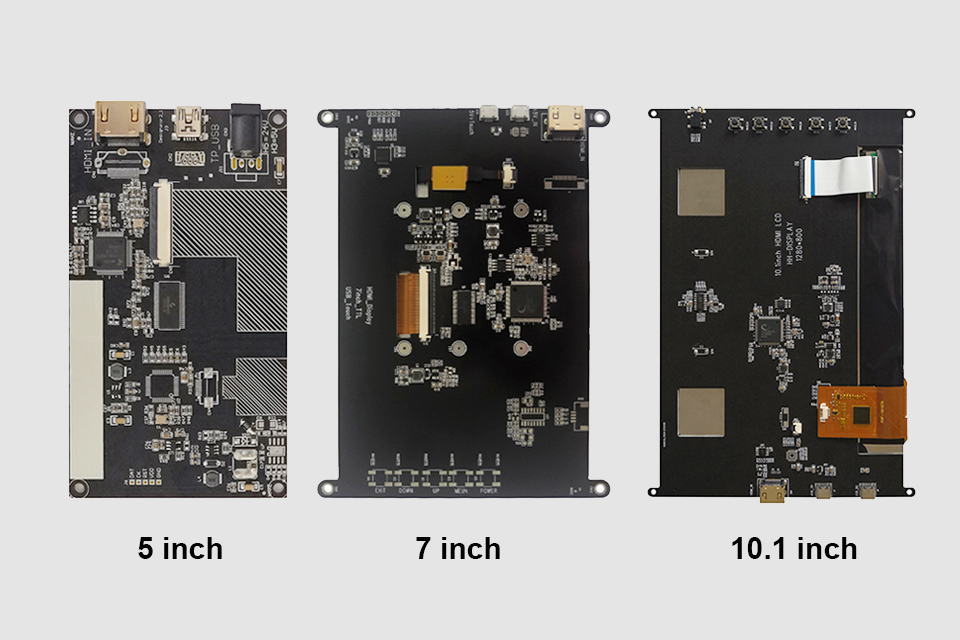

LCD driver boards come in various forms to suit different applications and lcd display types. Each lcd driver board is designed to meet specific requirements of the display panel it controls, which is why there is no one-size-fits-all solution. The type of display, its size, its resolution, and its special features can all impact the complexity of the lcd driver board. Some lcd driver boards are built for small, embedded displays while others are designed for large, high-resolution panels and include features to interface with vga, dvi, displayport and more. The variability of lcd driver boards is directly linked to the variety of available lcds. The lcd driver boards ensures the proper functioning of their respective display panel.

The different types of lcd driver boards cater to the diverse requirements of the display market. For example, a driver board for a basic monochrome LCD will be simpler than one for a full-color, high-definition tft lcd. Some lcd driver boards are equipped with additional features such as USB connectivity, touch interfaces, or additional driver circuits. Furthermore, the choice of interface (such as HDMI, VGA, LVDS, or EDP) also influences the design of the driver board. The existence of diverse lcd driver boards enables flexibility for various applications and requirements. The need for different driver boards is dictated by the specific requirements of the display it is connected to. A driver board designed for a laptop display needs to be compact and low-power. The lcd driver boards make it possible to use different types of panels.

Touch panels are a common feature in modern LCD devices, and they integrate seamlessly with LCDs to offer a responsive user interface. The integration typically involves the addition of a transparent layer on top of the screen panel. This layer allows the device to detect physical touch events and interpret them as inputs. There are mainly two types of touch technologies used in display systems: capacitive and resistive. Each of these has distinct operational and performance characteristics. Touch panel integration allows direct interaction with the content on the display making it more intuitive.

Capacitive touch panels are more prevalent in modern smartphones and tablets due to their high responsiveness, accuracy, and support for multi-touch. These panels work by sensing changes in electrical capacitance when a finger or stylus touches the surface of the screen. Resistive touch panels, on the other hand, use two thin layers of electrically conductive material that are pressed together when touched. Resistive technology is less expensive to manufacture but offers lower accuracy and does not support multi-touch. Capacitive touch panels are known for their durability and better display clarity. The touch panel connects to a touch controller and sends the location of the touch to the processor. The choice between capacitive and resistive touch panel depends on the application and cost requirements. The touch controller handles the processing of the data from the touch panel.

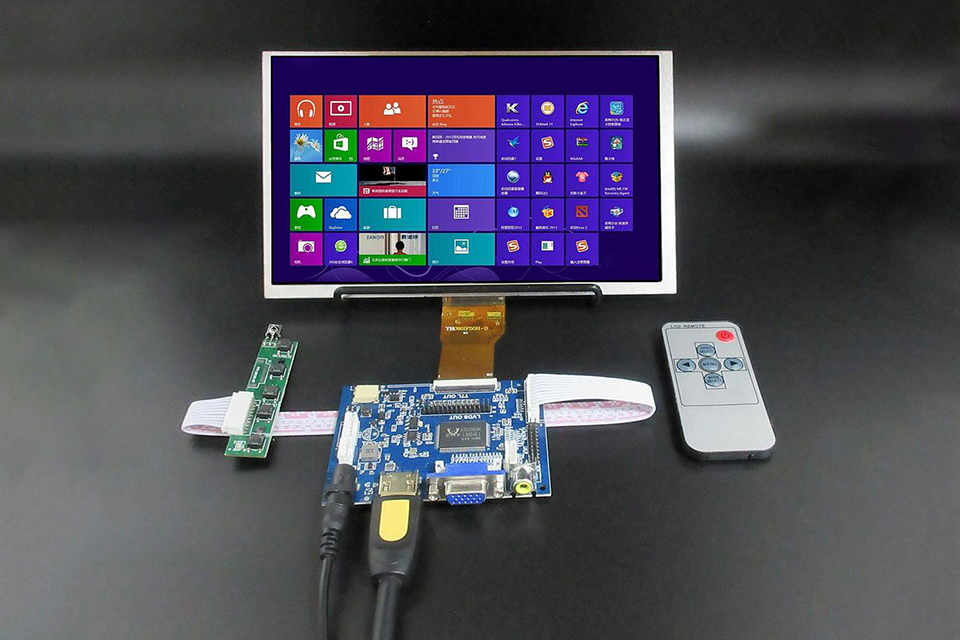

Selecting the correct driver board for a specific project is critical for success. The first and most important consideration is to match the driver board to your lcd display type. Make sure that the driver board is compatible with your particular lcd screen, including the resolution, interface, and voltage requirements. Check if the driver board supports the required interface, be it HDMI, VGA, LVDS, or EDP. Secondly, assess the specific requirements of the project. For instance, if you plan to use the display with a raspberry pi or a specific processor, ensure that the driver board is compatible and provides the appropriate input connections. Choosing a driver board with necessary interfaces is essential for project success. The driver board should be able to handle the required resolution and refresh rates.

Another critical aspect is the availability of good documentation and support for the chosen driver board. In some cases firmware updates might be needed to achieve desired performance. Always look for a driver board that fits within your budget, but don’t sacrifice quality for cost. If the display will be part of a commercial product, quality and durability of the driver board should be a priority. Also consider the power requirements of the board and how well it matches the power supply in your project. Some driver boards require additional components like an inverter for backlight, that should also be taken into consideration. Finally, ensure you have all necessary cables or connectors needed to hook it up. Proper selection ensures the display works as intended and provides a clear visual interface. Selecting the right display driver board requires careful consideration of all technical specifications.

Understanding the intricate dance between the driver board, controller, and lcd display components unlocks the secrets behind the visual interfaces we use every day. By understanding the role each part plays in the system, we are better equipped to handle our own projects and troubleshoot any problems with existing systems. This knowledge can be further enhanced by using a second cable for testing purposes. Ultimately, understanding these systems allows for a deeper appreciation of the electronics that make our modern world function.

| Feature | Driver Board | LCD Controller |

|---|---|---|

| Primary Function | Powering and managing the LCD panel itself | Processing input signals for display |

| Interaction | Directly interfaces with display panel | Acts as the “brain” interpreting signals |

| Power Management | Manages voltage and current distribution | Less involved in power distribution |

| Key Components | Power supplies, signal drivers, amplifiers | Processor, signal converters, osd circuits |

| Task | Activates pixels to create image | Prepares signal for display |

| Touch Panel Type | Technology | Accuracy | Multi-Touch | Cost |

|---|---|---|---|---|

| Capacitive | Senses changes in capacitance | High | Yes | Higher |

| Resistive | Pressing two layers together | Lower | No | Lower |

The world of virtual reality (VR) and augmented reality (AR) is rapidly evolving, and at the heart of this transformation lies a critical component: the display.

This article dives into the fascinating realm of small OLED displays, exploring their unique characteristics, applications, and the technology that makes them possible.

The 16×2 LCD module, a cornerstone of embedded systems, is a fantastic tool for displaying textual information.

This article explores the fascinating world of LCD (Liquid Crystal Display) technology, focusing on the essential role of driver boards and controllers in making these displays function.

Are you confused by all the different display technologies out there? From LCD to OLED, and even further, to AMOLED and Super AMOLED, the choices can be overwhelming.

This article explores how to connect an LCD screen to a Raspberry Pi using an HDMI driver board, essentially turning your single-board computer into a miniature HDMI monitor.

This article dives into the exciting world of augmented reality (ar) lenses, specifically focusing on the development and potential of an interchangeable lens system for ar glasses.

This article dives deep into the lifespan and durability of OLED (Organic Light Emitting Diode) displays compared to LCD (Liquid Crystal Display) screens.

@ 2025 display-module. All right reserved.

Fill out the form below, and we will be in touch shortly.